Tel : 94870 36000, 94860 36000, 94890 36000

Top 10 Ball Screws for Sale How to Choose the Best One?

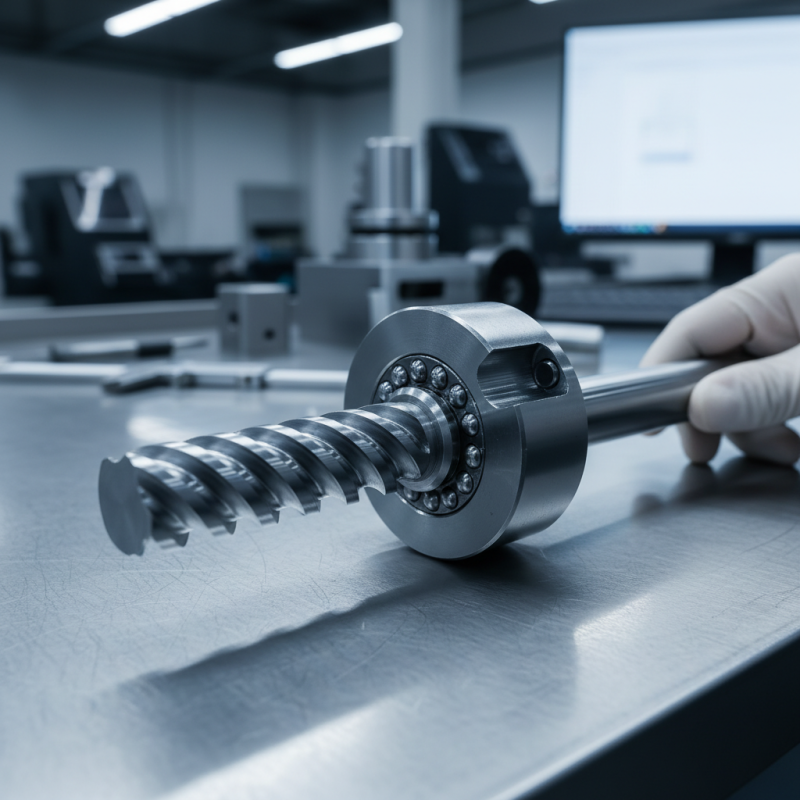

Choosing the right ball screw for sale is crucial for industrial applications. Demand for precision components is rising, with the global market projected to reach $10 billion by 2025. Ball screws are essential in machinery due to their accuracy and efficiency. They significantly reduce friction, which enhances performance.

Many manufacturers provide various types of ball screws. However, not all will meet specific needs. One should consider factors such as load capacity, size, and material. The wrong choice can lead to operational failures. Reports indicate that improper screw selection can affect productivity by up to 30%.

Fortunately, with a thorough understanding of requirements, selecting the best ball screw for sale becomes manageable. Ensuring compatibility with existing systems is vital. Investing in quality components pays off in the long run, improving performance and reliability.

Table of Contents [Hide]

Understanding Ball Screws: Function and Applications

Ball screws are vital components in various machinery and automation systems. They convert rotary motion into linear motion with efficiency. This functionality makes them ideal for applications in robotics, CNC machinery, and automotive systems. Their design minimizes friction, allowing for smoother operation and extended life cycles. However, choosing the right ball screw requires careful consideration.

When selecting a ball screw, factors like load weight, precision, and speed must be addressed. Each application demands specific features. Many engineers face challenges in balancing these aspects. The trade-off between speed and load capacity can be tricky. Sometimes, precision is prioritized over speed, which can lead to slower performance. Remember, the ideal choice is rarely clear-cut.

Understanding your application's needs is crucial. Consider consulting with experts for advice. This approach can clarify which specifications matter the most. Don't overlook the potential for cost-saving alternatives that still meet your criteria. Learning from past experiences is key. Analyze which choices worked well and which didn’t. This reflective process can guide future decisions.

Key Factors to Consider When Choosing Ball Screws

When selecting ball screws, several key factors should be evaluated. First, consider the load capacity. Different applications require different load-bearing capacities. Ensure that the ball screw can handle the expected loads without failure. Size is another critical factor. A ball screw must fit within the spatial constraints of your assembly while delivering adequate performance.

Material quality cannot be overlooked. High-quality materials can improve durability and performance. Corrosion resistance is essential, especially in harsh environments. Look for screws that meet industry standards for quality.

Tips: Always inspect specifications carefully. Small details can lead to big problems. Consider consulting with industry experts if you're unsure about your choices.

Remember to evaluate the end cap design as well. It can affect the screw's overall function and efficiency. Reassess your choice if you notice a mismatch. Sometimes, even minor changes in design can lead to significant performance improvements. Make thoughtful decisions for better results.

Review of the Top 10 Ball Screws Available on the Market

When selecting the best ball screws, understanding their features and specifications is crucial. Ball screws convert rotary motion into linear motion. High precision is essential for applications in manufacturing and robotics. According to recent industry reports, ball screws can achieve positioning accuracy of up to 0.01 mm. This level of precision is vital in minimizing errors in production processes.

Load capacity is another significant aspect. Different ball screws have varying capacities, influenced by material strength and design. Some sources indicate that the load capacity can range from a few hundred to several thousand Newtons. Users must evaluate their load requirements carefully. Oversized screws may lead to unnecessary costs. Conversely, underestimating requirements can result in mechanical failures.

Installation and maintenance also matter. Regular maintenance can extend the lifespan of ball screws significantly. Industry studies show a direct correlation between maintenance frequency and performance. Unfortunately, many neglect this aspect, leading to premature wear. Keeping an eye on lubrication and wear can help avoid expensive replacements. Effective management ensures reliability and efficiency in operations.

Top 10 Ball Screws for Sale - How to Choose the Best One?

| Model | Load Capacity (N) | Lead (mm) | Length (mm) | Accuracy | Price (USD) |

|---|---|---|---|---|---|

| Model A | 5000 | 10 | 1000 | C7 | 300 |

| Model B | 7000 | 12 | 1200 | C5 | 450 |

| Model C | 6000 | 15 | 1500 | C7 | 350 |

| Model D | 8000 | 18 | 1600 | C5 | 500 |

| Model E | 9000 | 20 | 1800 | C3 | 600 |

Comparative Analysis of Ball Screw Brands and Specifications

When considering ball screws, it’s crucial to analyze various brands and their specifications. Different manufacturers offer unique designs and materials. For instance, studies have shown that about 70% of users prioritize preload levels and efficiency. Preload can significantly impact precision. A lower preload may yield higher speed but at the cost of backlash.

Durability is another vital aspect. Data indicates that high-quality ball screws can last between 5,000 to 10,000 kilometers of travel. However, factors like lubrication and environmental conditions may influence this lifespan. Some brands excel in offering corrosion-resistant coatings, making them ideal for harsh environments. On the flip side, many brands commonly face recurring complaints about noise levels in operation.

Power consumption is also an essential factor. The efficiency ratings can vary widely. A report from an industry review stated that some ball screws operate at an efficiency of 90% or higher. Yet, others may only reach around 75%. This disparity highlights the necessity of thorough research. Without it, users may install components that do not align with their operational goals, leading to performance issues. Making informed choices is key to optimizing functionality.

Top 10 Ball Screws Performance Comparison

Maintenance Tips for Prolonging the Life of Ball Screws

Ball screws are essential components in many mechanical systems. To ensure their longevity, proper maintenance is crucial. Regular inspection is a good place to start. Look for any signs of wear or damage. Small issues can escalate if left unchecked. Keep the ball screw clean to avoid contamination. Dust and debris can lead to premature failure.

Lubrication is another important aspect. Use the right type of lubricant as recommended. Apply it at regular intervals to keep the balls rolling smoothly. Excessive lubrication can be just as harmful. It might attract dirt and grime. Keep your workspace organized to avoid accidents that could damage the screws. A cluttered area can lead to mistakes, like dropping components.

Pay attention to alignment during installation. Misalignment can stress the screw and lead to quicker wear. Adjustments might be necessary after installation. Moreover, always follow recommended load limits. Overloading can cause deformities and reduce performance. Reflect on these practices. Regular maintenance is often overlooked but can significantly extend the life of ball screws. If neglected, it can result in costly downtime and repairs.