Tel : 94870 36000, 94860 36000, 94890 36000

What is a Thermal Paper Roll Manufacturer and Their Importance?

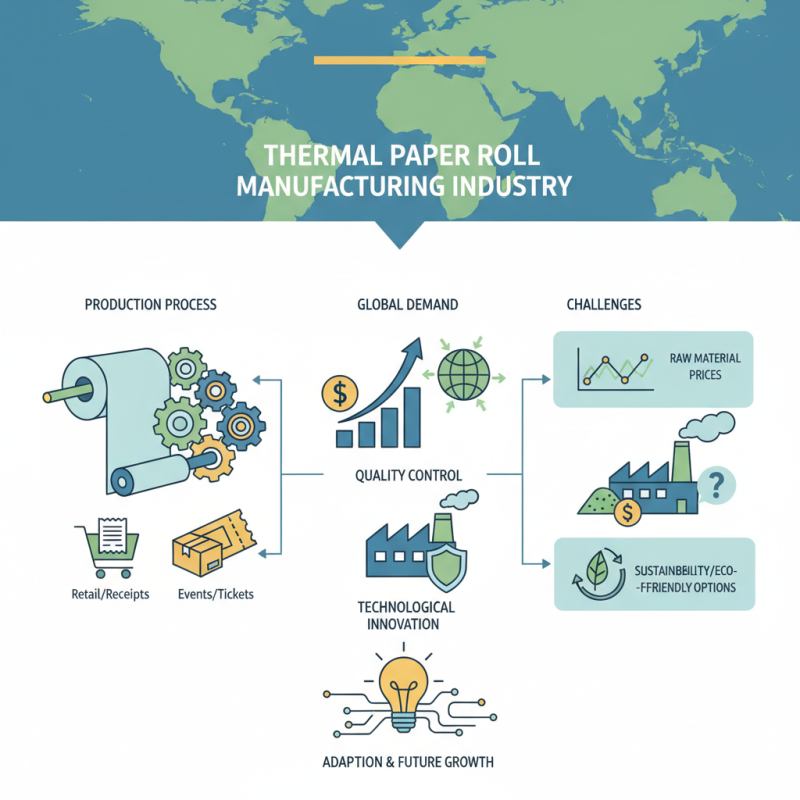

thermal paper roll manufacturers play a crucial role in various industries today. They produce paper that easily develops images when exposed to heat. This technology is widely used in receipts, labels, and tickets. The global demand for thermal paper is booming, projected to reach $5.5 billion by 2027.

These manufacturers ensure quality and consistency in their products. However, there are challenges they face. Fluctuating raw material prices can affect production quality. Additionally, sustainability practices are becoming essential. Many companies are now looking for eco-friendly options.

The process of developing thermal paper involves several steps. From coating to cutting, every detail matters. Manufacturers must address quality control rigorously. Customers rely on them for durability and user satisfaction. As technology evolves, thermal paper roll manufacturers need to adapt quickly. They must innovate to meet changing market demands.

Table of Contents [Hide]

Definition of a Thermal Paper Roll Manufacturer

A thermal paper roll manufacturer plays a vital role in today’s printing industry. These manufacturers produce rolls of paper that rely on heat to generate printed images. This technology is widely used in various sectors, including retail, healthcare, and logistics. The paper is coated with a thermal reactive material. When exposed to heat, it turns dark, creating text and images.

Quality is paramount for a thermal paper roll manufacturer. They must ensure that the paper adheres to specific standards. Variability in quality can lead to issues with printing equipment. Manufacturers often face challenges like sourcing high-quality raw materials. Monitoring production processes for consistency is essential.

Furthermore, manufacturers must keep an eye on market demands. The need for environmentally friendly options is growing. Some manufacturers are exploring sustainable resources. However, embracing these practices can be daunting. The balance between innovation and cost efficiency remains a constant concern.

Thermal Paper Roll Production Statistics

The Manufacturing Process of Thermal Paper Rolls

The manufacturing process of thermal paper rolls is intricate yet fascinating. Thermal paper, widely used for receipts and labels, undergoes several key stages. First, a base paper is selected. This paper is typically coated with a special thermal layer that reacts when exposed to heat. This layer is crucial. Without it, the paper wouldn't print images or text.

Next, the coating operation is performed. This involves mixing chemicals that create the thermal reaction. The coating is applied evenly to ensure consistent performance. According to industry reports, the global market for thermal paper was valued at over $3 billion in 2022, emphasizing its significant role in various sectors.

After coating, the paper rolls are dried and cut to the desired sizes. Precision in cutting is vital. If the rolls are not uniform, it affects usability in printers. A recent study highlighted that about 15% of thermal paper rolls face issues because of improper cutting. This reveals a need for rigorous quality control in manufacturing. Despite advancements, ongoing discussions exist about sustainability. The industry is exploring eco-friendly alternatives to traditional materials.

Types of Thermal Paper and Their Applications

Thermal paper comes in various types, each serving distinct needs. One common type is plain thermal paper, widely used in point-of-sale systems. It produces sharp, clear images when heated, making it ideal for receipts. Another type is thermal label paper, often used for shipping labels. It withstands different environments, ensuring that essential information remains readable.

Specialty thermal paper has unique features. For example, some have a water-resistant coating. This type is ideal for outdoor use, where moisture could be an issue. There are also color-changing thermal papers, which reveal hidden messages upon exposure to heat. These can add a fun element for promotions or special events.

Interestingly, not all thermal papers are created equal. The quality can vary, impacting print longevity and clarity. Some may fade within months, while others resist wear and tear longer. Manufacturers need to monitor these qualities closely. It’s essential to choose the right type for its intended use. A mismatch can lead to frustration and wasted resources.

What is a Thermal Paper Roll Manufacturer and Their Importance? - Types of Thermal Paper and Their Applications

| Type of Thermal Paper | Application | Characteristics | Common Uses |

|---|---|---|---|

| Direct Thermal Paper | Point of Sale Receipts | Sensitive to heat, no ink required | Retail, Restaurants |

| Thermal Transfer Paper | Label Printing | Requires ribbon, durable and high-resolution | Logistics, Warehousing |

| Thermal Self-adhesive Paper | Freight Labels | Adhesive back, easy application | Shipping, Inventory Management |

| Waterproof Thermal Paper | Marine and Outdoor Applications | Water resistant, durable print | Food Processing, Outdoor Events |

| High-temperature Thermal Paper | Industrial Use | Resistant to high temperatures | Manufacturing, Automotive |

Importance of Quality Standards in Thermal Paper Production

Thermal paper plays a vital role in various industries, from retail to healthcare. The quality of thermal paper is critical for ensuring clear prints and durability. According to a report by Smithers Pira, the demand for thermal paper is expected to grow steadily, reaching 1.6 million metric tons by 2025. This growth emphasizes the need for high-quality production standards.

Quality standards in thermal paper production directly impact longevity and performance. Papers lacking proper specifications can fade quickly or produce illegible prints. For instance, papers not meeting the appropriate chemical composition can lead to issues in thermal transfer printers. According to a study by the Technical Association of the Pulp and Paper Industry (TAPPI), products with subpar quality often require reprints, which increases costs for businesses.

Manufacturers must understand these challenges. Rigorous testing processes, industry certifications, and adherence to safety standards are essential. However, some manufacturers still overlook these practices, resulting in quality inconsistencies. This gap can compromise customer satisfaction and brand reputation. As the industry evolves, focusing on quality could avoid setbacks and contribute to long-term success.

Market Trends and Future of Thermal Paper Industry

The thermal paper industry is witnessing significant market trends as technology advances. According to a recent report from Industry Research, the global thermal paper market is projected to grow at a rate of 5.2% annually from 2023 to 2030. Increased demand for thermal receipts in retail, logistics, and banking sectors drives this growth. Suppliers are innovating to meet sustainability goals, which adds complexity to the supply chain.

The shift towards digital solutions also impacts the market. As businesses adopt more digital transactions, the need for thermal paper may fluctuate. This presents both challenges and opportunities for manufacturers. Some companies face pressure to adapt their production methods to minimize environmental impact. While many are implementing eco-friendly practices, not all meet stringent standards.

Market players must navigate these changes carefully. The introduction of biodegradable thermal paper is a step in the right direction. However, the costs can deter smaller manufacturers from transitioning. As competition increases, maintaining quality while exploring sustainable options will be crucial. The balance between innovation and practical implementation remains a critical issue in the industry's future.